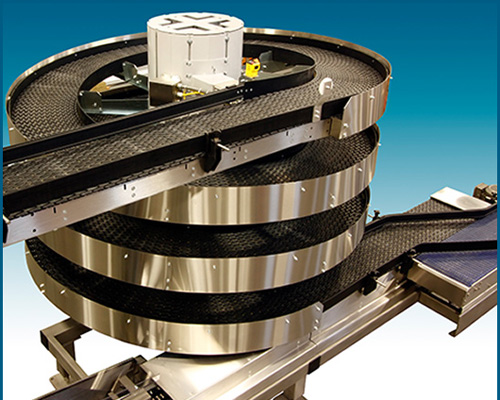

The Ryson Mass Flow Spirals are designed to handle full and empty bottles, cans, jars and other similar containers.

Products are conveyed up or down in a continuous mass flow. Ryson Spirals have a small footprint and provide considerable space savings compared to conventional methods.

The Mass Flow Spirals are based on the already proven and reliable Ryson Spiral technology. Only one drive motor is needed, equating to substantial savings in controls and systems integration. All Ryson Spirals are designed for low maintenance and long life. Many spirals operate 24 hours a day, 7 days a week.

The Mass Flow Spirals are equipped with extended in and outfeed tangents to facilitate smooth side transfer to and from external conveyors. They can be delivered with 12”, 16” or 20” wide slats with capacities of up to 800, 1,200 2,000 bottles or cans per minute respectively. They are also available in powder coated carbon steel, stainless steel and washdown versions.

Controls

Most of our spirals are shipped without controls because they are normally integrated into an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and the other for the overload protection device.

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. Ryson offers several controls options including :

- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.

Integration

All Ryson Spirals are shop tested prior to shipment, but optimal performance depends on proper integration with the overall conveyor system.

REQUEST INFORMATION/QUOTE