“A Spiral for the Tough Jobs.”

The new Ryson High Capacity Spirals are in response to our customers need to go higher and handle more weight.

The new spirals handle double the capacity of our regular spirals and ship in one piece which drastically reduce the time and cost of installation.

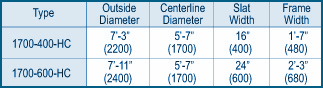

The load capacity is 75 lbs. per linear foot of conveyor for speeds up to 200 FPM. The total weight capacity in the spiral at any one time is 3200 lbs. Only one drive motor is required, resulting in substantial savings in energy, controls and system integration.

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

REQUEST INFORMATION/QUOTE

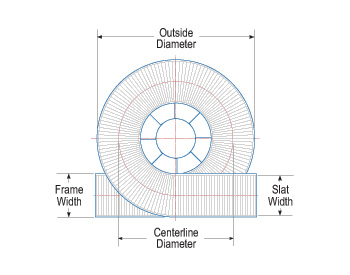

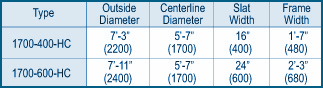

Product Specifications

Ryson Spirals are designed for low maintenance and long life. An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs.

Modular Design:

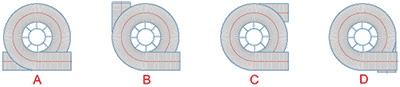

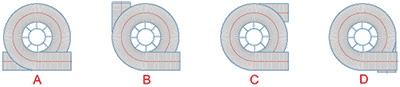

An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

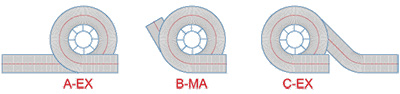

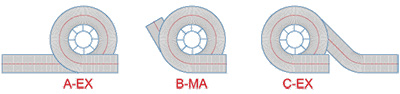

The position of the in-feed tangent on up spirals and out-feed tangent on down spirals can be customized to meet specific layout requirements. Samples are shown below (A-EX, B-MA and C-EX). A horizontal section is provided at in and out-feed to assure smooth transition between conveyors. All Ryson Spirals are available in powder coated carbon steel, stainless steel, washdown, and freezer versions.

Controls

Most of our spirals are shipped without controls because they are normally integrated into an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and the other for the overload protection device.

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. Ryson offers several controls options including :

- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.

Integration

All Ryson Spirals are shop tested prior to shipment, but optimal performance depends on proper integration with the overall conveyor system.