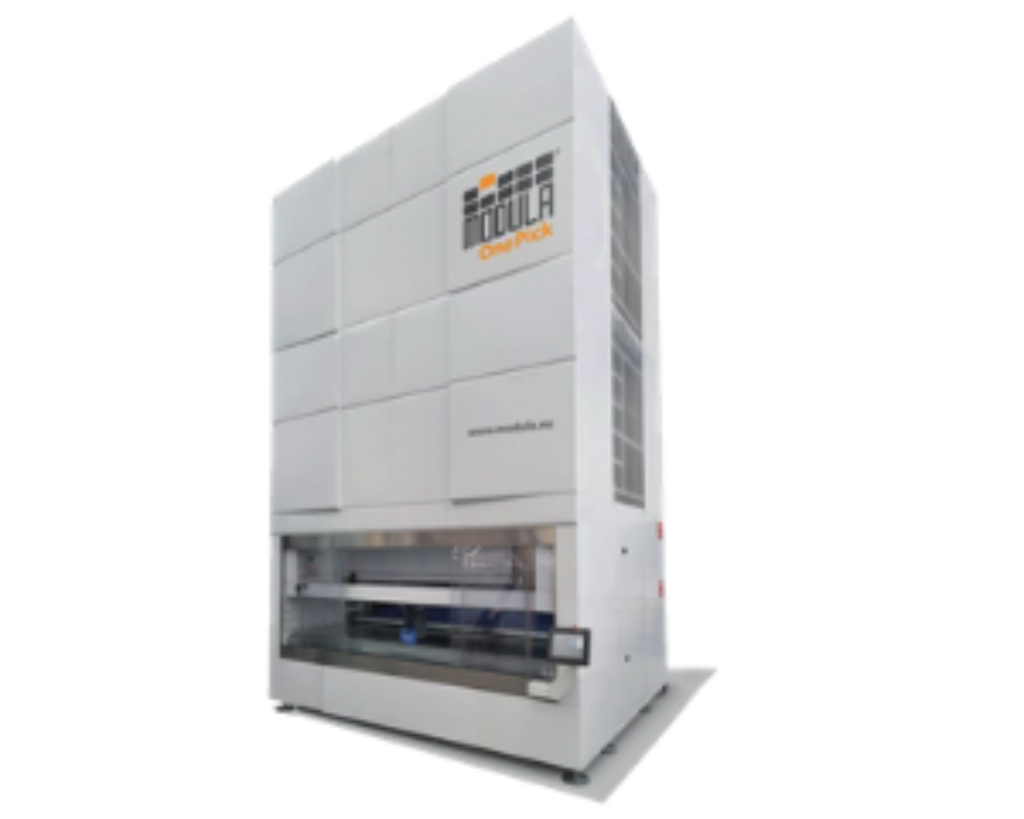

An Automatic Bay That Doesn’t Require Operators.

Modula OnePick is an automatic vertical warehouse with a special picking bay equipped with a Cartesian robot moving along 2 axes (X & Y).

The bay is set at a predefined height so it integrates seamlessly with rollers, conveyors, belts and other systems completely autonomously.

Sophistication in Automation

OnePick is the system for stocking in the same warehouse boxes, bins, and containers with:

- Different weights

- Different volumes

- Different sizes

- Different dimensions

What it is and how it works

OnePick combined with a handling system allows the installation of an automatic vertical warehouse even in areas that are difficult to access, uncomfortable or far from where the goods are needed. OnePick’s operation is based on WMS software which, amongst other things, also maps the location of the tray containers. The gripper device is guided by this mapping and retrieves the requested items autonomously. This type of automatic transport system will then be able to convey the retrieved materials to another location, even if far away.

Like a Modula Lift, it:

- Saves floor space

- Stores items safely

- Automatically manages inventory

- Tracks items

- Saves picking time

- Prevents retrieval and delivery phase errors

Modula Lift is available in these models:

• MA & MA-D

• MC & MC-D

• MX & MX-D

• ML & ML-D

REQUEST INFORMATION/QUOTE